The stoichiometric mass ratio of oxide to metal is 1.79 :1. Videoclip of 0.5 grams of manganese dioxide / aluminum thermite being ignited with a Mini bulb igniter WMV format, (436 kb), AVI format, (1.4 Mb), Ignited readily with magnesium ribbon, and was also successfully ignited with a Mini bulb igniter. Observations: Reluctantly ignited with a propane torch. The stoichiometric mass ratio of oxide to metal is 2.42 :1. Videoclip of 0.5 grams of copper oxide / magnesium thermite being ignited with a Mini bulb igniter WMV format, (629 kb), AVI format, (1.1 Mb) A Mini bulb igniter was also successful in igniting this thermite. Burned instantaneously with a bright flash. Observations: Ignited easily with a propane torch. The stoichiometric mass ratio of oxide to metal is 3.3:1 Videoclip of 0.5 grams of copper oxide / aluminum thermite being ignited with a Mini bulb igniter WMV format, (519 kb), AVI format, (1.1 Mb), Burned instantaneously with a hot, white flash.

Ignited readily with magnesium ribbon and also with a Mini bulb igniter. Observations: Could not be ignited with a propane torch. The stoichiometric mass ratio of oxide to metal is 4.56:1. Burned quickly, with a bright white flash. Could also be ignited with a Mini bulb igniter. Observations: Easily ignited with a propane torch. The stoichiometric mass ratio of oxide to metal is 2.23:1. This is a modified version of the "classic" thermite. Burned with a medium quickness, emitting lots of iron "sparklers". The stoichiometric mass ratio of oxide to metal is 2.96:1. No ignition powder was used with these igniters, rather, the filament was merely placed in direct contact with the thermite powder. For some formulations, an electrically initiated Mini bulb igniter was also used. If this failed, a ribbon of burning magnesium was used. Three different means of igniting the thermite were tried. Qualitatively, the rate of burning was observed, and the appearance of the resulting reaction. Of this, a small 0.5 gram sample was ignited to ascertain how readily the formulation could be ignited. Ten gram batches of each formulation were prepared. Appendix A demonstrates how the change in enthalpy is calculated. A negative sign indicates that heat is released by the reaction. Since the reacting metal is a lot more precious than the oxides, the heat released per gram of metal reactant is also indicated. All the oxides had been obtained from a local pottery supply shop.įor each of these, the balanced reaction equation and the change in enthalpy (heat released) per gram of reactants is presented. The magnesium was, for safety concerns, a relatively coarse 230 mesh (60 micrometer), and was non-passivated. The aluminum used in these experiments was West System 420 atomized aluminum powder. Those chosen for this investigation were based on what was available "on hand".

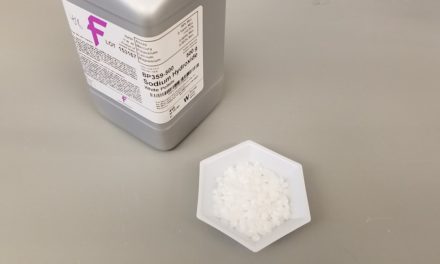

The oxides considered are those commonly available, typically used as pigments. For all of these, two reacting metals were considered - aluminum and magnesium. This webpage explores the theoretical properties and combustion characteristics of several of thermite formulations.

In particular, for rapid ignition of hard-to-light propellants. The large quantity of released heat, the rapid combustion, the abundance of condensed-phase products, and the absence of appreciable gaseous products combine to make their use appealing in certain applications. Thermites are of interest to the amateur rocketeer due to their potential use as an effective rocket motor igniter composition. Also produced is a great deal of thermal energy. If the reacting metal is magnesium, the products are magnesium monoxide (MgO) and the elemental metal. If the reacting metal is aluminum, the products are aluminium oxide (Al 2O 3) and the elemental metal from the original oxide. The term thermite is also used to refer to the mixture of two such compounds. Richard Nakka's Experimental Rocketry Web SiteĪ thermite reaction is one in which a metal (usually aluminum or magnesium) is oxidized by an oxide of another metal. Richard Nakka's Experimental Rocketry Site

0 kommentar(er)

0 kommentar(er)